Silica Sand to Glass

Silica sand to glass represents an essential transition in modern manufacturing. Because silica has a high level of purity and can withstand high temperatures, it becomes a crucial factor in producing clear, durable glass for windows, bottles, and high-tech applications. As a result, quality silica means quality glass, and Universal Silica provides quality silica.

Improving Surface Stability and playability

As silica is the backbone of contemporary glass manufacturing, it offers very high purity and uniform grain size, which are ideal raw materials for producing glass of maximum clarity, strength, and durability. Unlike ordinary sand, it contains a high amount of silicon dioxide, sometimes above 98%, and has very few impurities, which leads to an essentially clear and defect-free product.

Who Uses Glass Made from Quartz Sand?

At what temperature does sand turn to Glass?

Melting sand into glass occurs by heating it to temperatures exceeding 1600–1700 °C (2912–3092 °F). Through this intense heat, the silica and all other sand transform into a homogeneous liquid, which can then be molded into various glass products.

How Is Glass Manufactured from Quartz Sand?

- Raw Material Sourcing : High purity silica sand, soda ash, and limestone are the base ingredients. Only a few deposits are acceptable as high-grade materials for glassmaking.

- Melting : The batch is heated in a furnace using either tank or crucible melting methods. Additives may be included to achieve desired characteristics or colors.

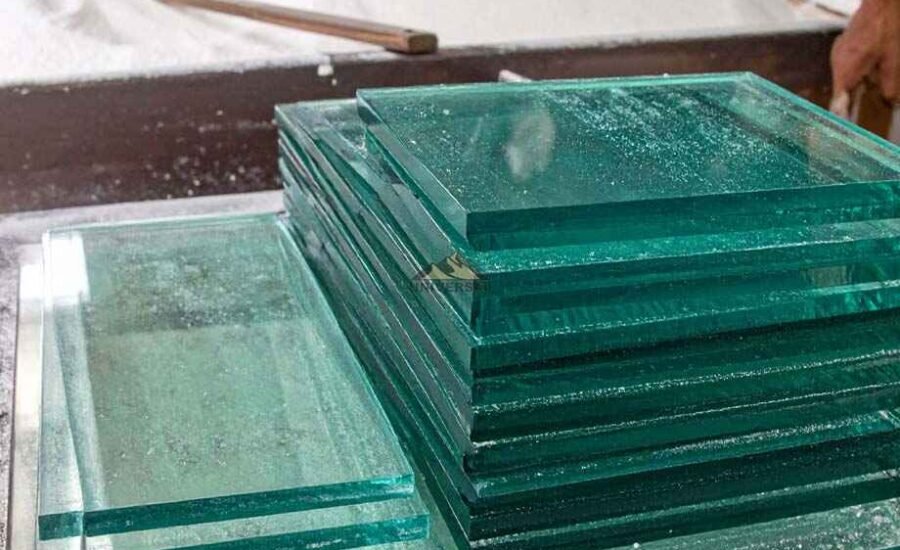

- Shaping and Forming : The moldable glass gets shaped using blow or press glass techniques. Flat glass gets formed with molten tin on a float process.

- Annealing and Finishing : Once the glass has been shaped, it is slowly cooled (annealed) to relieve stress; finished glass can be polished, cut, or coated depending on the application.

Why Silica Sand Is Critical in the Glass Industry?

The purity of silica sand unequivocally affects the performance of the final glass product. Especially for applications like solar panels or safety glass, quartz sand of the highest clarity and chemical stability is required. Only a meager 1% of the total extraction of sand around the globe can achieve that level of purity.